Technical visits

Technical visits to 5 locations will depart from Brussels Centre on Friday morning for those registered. A limited fee will be charged. Access rules might apply.

1. SCK CEN, the Belgian Nuclear Research Centre

1.1 Heavy Liquid Metal technology complex

Since the beginning of the MYRRHA project in 1998, SCK CEN has launched a strong R&D support program to address the main design challenges, in particular those related to the use of liquid Lead-Bismuth Eutectic (LBE) as reactor coolant and spallation target. In this frame SCK CEN has constructed and commissioned various LBE test facilities such as E-SCAPE (European SCAle Pool Experiment) and COMPLOT (COMPonents LOop Testing) for thermal hydraulic testing, HELIOS3 (HEavy LIquid metal Oxygen conditioning System) and MEXICO (Mass EXchange In Continuous Operation) for coolant chemistry control, CRAFT (Corrosion Research for Advanced fast Reactor Technologies) and LIMETS (LIquid METal conditioning System) for material testing, RHAPTER (Remote HAndling Proof of principle TEst Rig) etc. These facilities are used for the qualification of the key materials and components of MYRRHA.

Since the beginning of the MYRRHA project in 1998, SCK CEN has launched a strong R&D support program to address the main design challenges, in particular those related to the use of liquid Lead-Bismuth Eutectic (LBE) as reactor coolant and spallation target. In this frame SCK CEN has constructed and commissioned various LBE test facilities such as E-SCAPE (European SCAle Pool Experiment) and COMPLOT (COMPonents LOop Testing) for thermal hydraulic testing, HELIOS3 (HEavy LIquid metal Oxygen conditioning System) and MEXICO (Mass EXchange In Continuous Operation) for coolant chemistry control, CRAFT (Corrosion Research for Advanced fast Reactor Technologies) and LIMETS (LIquid METal conditioning System) for material testing, RHAPTER (Remote HAndling Proof of principle TEst Rig) etc. These facilities are used for the qualification of the key materials and components of MYRRHA.

1.2 HADES

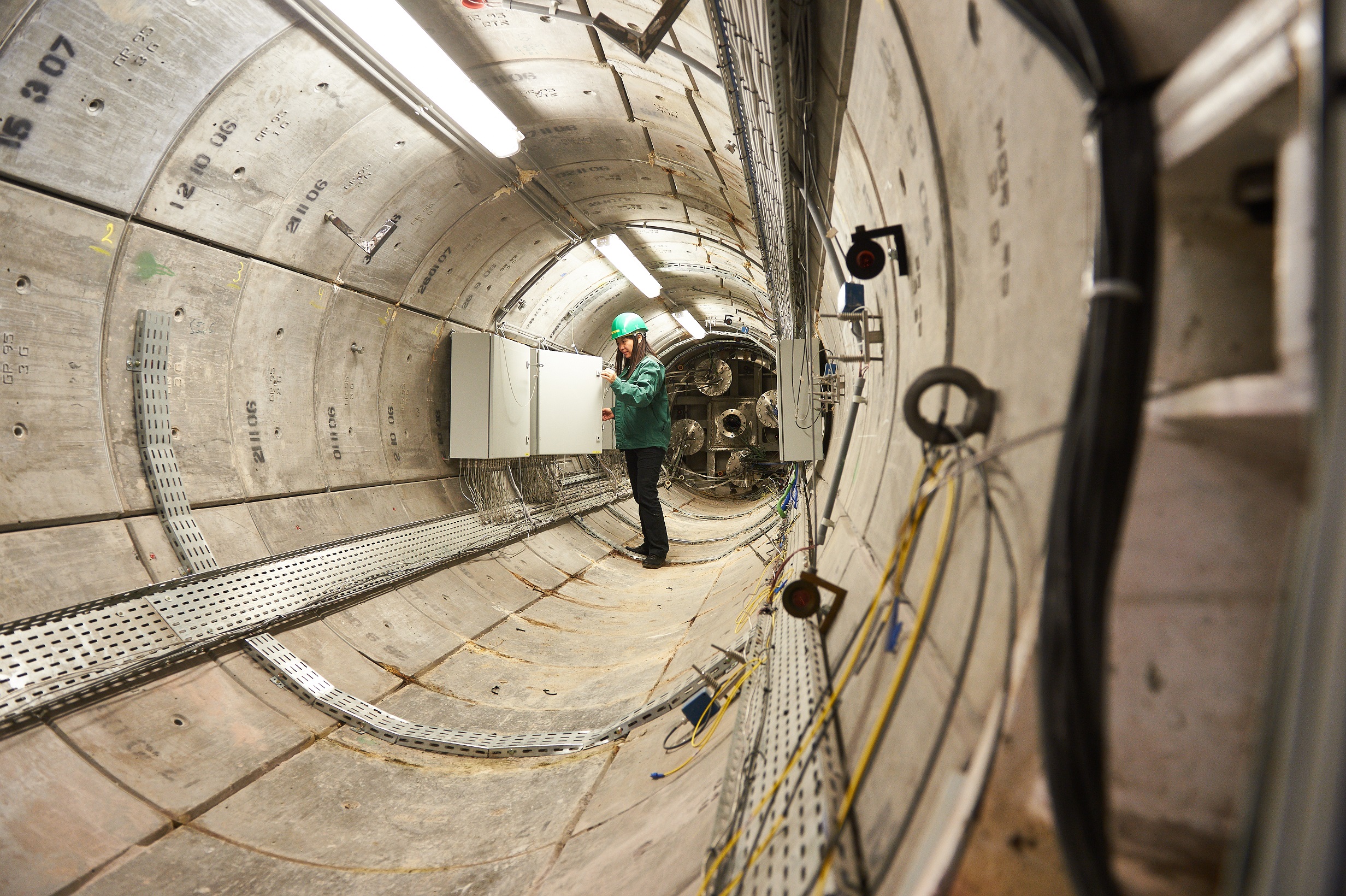

The HADES laboratory lies at a depth of 225 meters under the domain of SCK CEN and allows the study of deep clay as an option for the disposal of long-lived and high-active nuclear waste. EIG EURIDICE, the Economic Interest Grouping between NIRAS/ONDRAF and SCK CEN, exploits this lab and executes scientific research. At the beginning of this century, the infrastructure was expanded with an additional gallery in order to execute experiments at large scale regarding the feasibility and the safety of storage of heat emitting nuclear waste.

The HADES laboratory lies at a depth of 225 meters under the domain of SCK CEN and allows the study of deep clay as an option for the disposal of long-lived and high-active nuclear waste. EIG EURIDICE, the Economic Interest Grouping between NIRAS/ONDRAF and SCK CEN, exploits this lab and executes scientific research. At the beginning of this century, the infrastructure was expanded with an additional gallery in order to execute experiments at large scale regarding the feasibility and the safety of storage of heat emitting nuclear waste.

1.3 Belgian Reactor 2

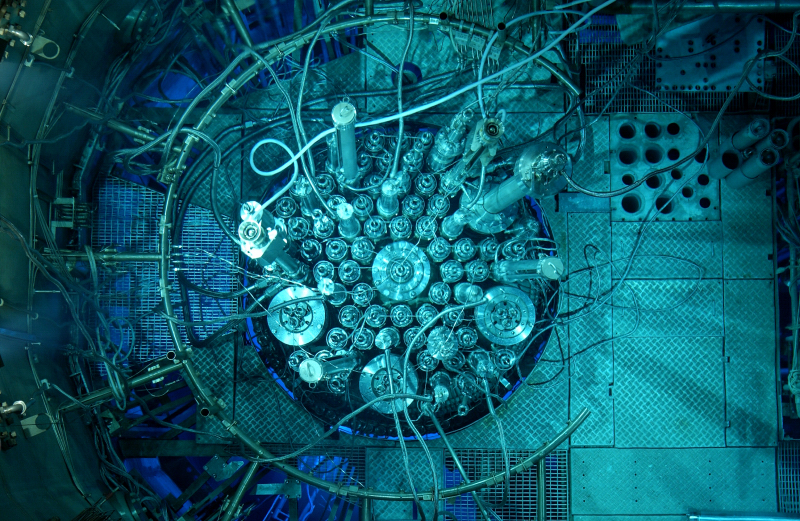

The Belgian Reactor 2 or BR2 is a materials test reactor. Since the start in 1962, it has been one of the most powerful research reactors in the world. It uses high-enriched uranium fuel and is moderated and cooled with water. BR2 tests nuclear fuels and materials for several reactor types and for the European nuclear fusion programm It contributes to guaranteeing the safety of current and future nuclear installations. BR2 is also an important instrument for the production of radioisotopes for medical and industrial applications, and for the irradiation (doping) of silicon for the microelectronics industry.

The Belgian Reactor 2 or BR2 is a materials test reactor. Since the start in 1962, it has been one of the most powerful research reactors in the world. It uses high-enriched uranium fuel and is moderated and cooled with water. BR2 tests nuclear fuels and materials for several reactor types and for the European nuclear fusion programm It contributes to guaranteeing the safety of current and future nuclear installations. BR2 is also an important instrument for the production of radioisotopes for medical and industrial applications, and for the irradiation (doping) of silicon for the microelectronics industry.

2. VKI

The von Karman Institute for Fluid Dynamics (VKI in short), founded in 1956 by Theodore von Karman, is an international non-profit organization (INPA) for post graduate education and research in fluid dynamics located in the south of Brussels. The educational program is based on the concept of “training in research by doing research”. The research and training activities are are spread over its three departments: Aeronautics and Aerospace, Environmental and Applied Fluid Dynamics, Turbomachinery and Propulsion. VKI has a large number of advanced experimental facilities, in total 43 wind tunnels and test rigs, available in the domain of aerospace, aeronautical, turbomachinery and industrial fluid dynamics. They cover a large span, ranging from low speed to hypersonic. Experimental research is complemented by an important activity in the domain of Computational Fluid Dynamics (CFD) which now covers about 40 % of the research activities.

The von Karman Institute for Fluid Dynamics (VKI in short), founded in 1956 by Theodore von Karman, is an international non-profit organization (INPA) for post graduate education and research in fluid dynamics located in the south of Brussels. The educational program is based on the concept of “training in research by doing research”. The research and training activities are are spread over its three departments: Aeronautics and Aerospace, Environmental and Applied Fluid Dynamics, Turbomachinery and Propulsion. VKI has a large number of advanced experimental facilities, in total 43 wind tunnels and test rigs, available in the domain of aerospace, aeronautical, turbomachinery and industrial fluid dynamics. They cover a large span, ranging from low speed to hypersonic. Experimental research is complemented by an important activity in the domain of Computational Fluid Dynamics (CFD) which now covers about 40 % of the research activities.

In the recent years, dedicated test benches for thermal hydraulic studies related to liquid metal flows have been developed such as MYRRHABELLE (water model facility of MYRRHA), SHAKESPEARE (a seismic table for the study of sloshing in case of a seismic event), MYRTE (a wind tunnel working with a gas at low Prandtl number).

3. NRG, Nuclear Research and consultancy Group

3.1 High Flux Reactor

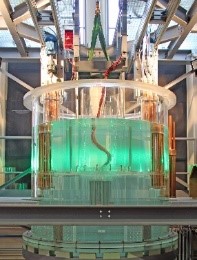

The High Flux Reactor at NRG was taken into operation in 1961. The HFR is a light water-cooled material test and irradiation reactor rated at 45 MW thermal power. It offers a constant, high neutron flux and is operational during a large number of days per year. The HFR offers various irradiation positions, in both the in-core and ex-core (pool side facility) region. This allows the HFR to achieve and simulate different irradiation conditions. Every day, the HFR plays an important role in society, by producing medical isotopes and facilitating energy supply research.

The High Flux Reactor at NRG was taken into operation in 1961. The HFR is a light water-cooled material test and irradiation reactor rated at 45 MW thermal power. It offers a constant, high neutron flux and is operational during a large number of days per year. The HFR offers various irradiation positions, in both the in-core and ex-core (pool side facility) region. This allows the HFR to achieve and simulate different irradiation conditions. Every day, the HFR plays an important role in society, by producing medical isotopes and facilitating energy supply research.

3.2 Hot Cell Laboratories and Workshop

In the Hot Cell Laboratories, radioactive materials irradiated in the High Flux Reactor can be processed for further research and production. These materials can be handled, processed, examined and repackaged on the HCL’s numerous cell lines. In some of these hot-cells radioactive waste is characterized and sorted in categories. The labs are equipped with radiation-shielding Hot Cells, lined with concrete or lead: a safe environment for working on (highly) radioactive materials. Irradiation experiments are fabricated and manufactured in the NRG workshop.

In the Hot Cell Laboratories, radioactive materials irradiated in the High Flux Reactor can be processed for further research and production. These materials can be handled, processed, examined and repackaged on the HCL’s numerous cell lines. In some of these hot-cells radioactive waste is characterized and sorted in categories. The labs are equipped with radiation-shielding Hot Cells, lined with concrete or lead: a safe environment for working on (highly) radioactive materials. Irradiation experiments are fabricated and manufactured in the NRG workshop.

4. IBA, Ion Beam Applications S.A. & CRC, Cyclotron Resource Centre

IBA is a global medical technology company focused on bringing integrated and innovative solutions for the diagnosis and treatment of cancer. The Company is the worldwide technology leader in the field of proton therapy, the most advanced form of radiation therapy available today. IBA’s proton therapy solutions are flexible and adaptable, allowing customers to choose from universal full scale proton therapy centers as well as compact, single room systems. In addition, IBA also has a radiation dosimetry business and develops particle accelerators for the medical world and industry.

Next to IBA, at the CRC of the University of Louvain-la-Neuve (UCL), SCK CEN is building and testing the injector part of the linear accelerator (LINAC) for the MYRRHA Accelerator Driven System, accelerating protons up to an energy of 5.9 MeV.

5. Westinghouse Electric Belgium: Pumps & Motors Workshop

During the life of a nuclear power plant, more than just routine inspections of a reactor coolant pump and its motor are necessary to help prevent unscheduled or extended outages. It is recommended that pumps and motors be disassembled and inspected periodically to maintain reliability. Westinghouse expanded its capabilities by opening the European Pump and Motor Center in Nivelles, Belgium in 2010. Centrally located within Europe and with more than 2,000 square meters of manufacturing space, the workshop is specifically designed to be a state-of-the-art facility to perform work on multiple radioactively contaminated pumps and motors in parallel.